EV battery testing with ICP® accelerometers: where selection criteria make a real difference

PCB Piezotronics attended Cenex Expo 2025 at UTAC Millbrook. The program again put design, engineering and test center‑stage, with dedicated sessions on batteries, simulation and validation. Three talking points stood out for battery R&D and validation this quarter:

- Real world data collection for battery durability to improve accelerated life testing.

- Safety challenged of conventional instrumentation in high voltage environments.

- Test & validation remains a headline track—align lab profiles and instrumentation with evolving requirements.

Battery Testing: Standards and Challenges

Modern programmes blend UN 38.3 transport, SAE J2380 vibration, in-vehicle RLDA, and low-frequency modal work. This can take place either on the vehicle itself or within laboratory-based simulation. The accelerometer is required to measure low-level signals below 1 Grms for durability cycles lasting in excess of 50 hours on each spatial axis. This is coupled with electrical factors such as charge/discharge cycling and environmental cycling of temperature and humidity. The testing then immediately switches to shock pulses of 50 g, which typically saturate a high-sensitivity accelerometer that is otherwise preferred for the 1 Grms durability cycle.

Transport compliance (UN 38.3 T3/T4 (cells, modules, packs))

- T3 Vibration: sine sweep 7→200→7 Hz in 15 minutes, 12 sweeps (3 hours) in three orthogonal axes.

- T4 Shock: half‑sine pulses (typ. 150 g/6 ms for small cells/packs, 50 g/11 ms for large packs), three pulses per direction over six directions.

Structural response of the battery to these shocks can be significantly more than the input, making selection of a high enough range device in this test scenario critical.

Vibration durability — SAE J2380

SAE J2380 gives guidance of how to develop PSD (power spectral density) vibration profiles from on-road test data. This enables the inputs to accurately take into consideration the road conditions, as well as the specific ride characteristics of the vehicle.

How a sports car or SUV impart fatigue into the battery greatly differ and need to be accounted for.

The generated vibration profile is applied through accelerated life testing on a shaker system to fast track 100,000 miles of structural loading.

Thermal and mechanical abuse testing – SAE J2464/ IEC 62660-2

The addition of thermal cycling from typically -40°C to 85°C can be considered outside of typical working environments, but is designed to inflict maximum design envelope condition on the battery.

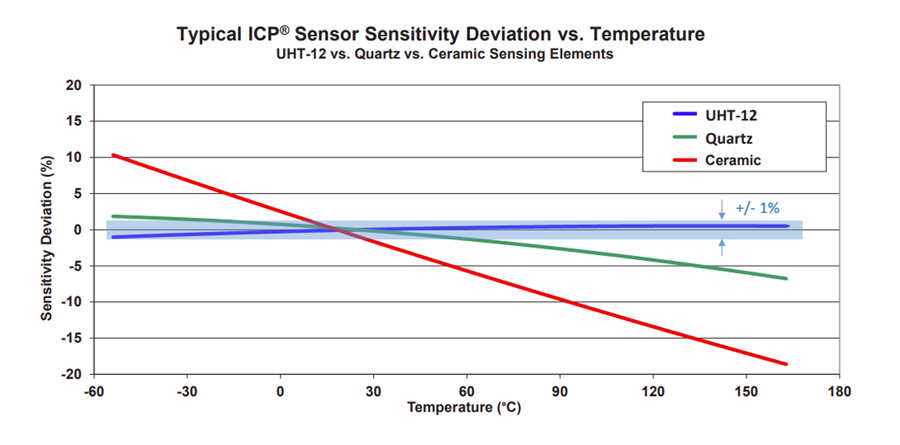

Our range of Quartz and UHT-12 low temperature coefficient accelerometer maintain absolute amplitude accuracy, where normal ceramic PZT accelerometer could see drifts of +/-10%.

Recommended accelerometers

Triaxial ICP® J356A4 series

- Electrically isolated accelerometer with wide frequency response to 10kHz.

- Sensitivities from 10, 50 and 100mV/g (50, 100 and 500g).

- Best for on vehicle and non-climatic shaker application.

- Now available in high voltage isolated design

Triaxial ICP® TLD356A34

- Low temperature coefficient with 50mV/g, 100g range,

- TEDS enabled.

- Quartz high stability sensing element for high amplitude accuracy in durability and shock testing during thermal cycling.

Triaxial ICP® J356A03

- Ultraminiature electrically isolated accelerometer for integration into the smallest possible spaces.

- Also available in high voltage isolated design for integration into battery packs.

Request a visit from a local engineer

Let’s review your assets and objectives on-site: book an onsite meeting and application review.